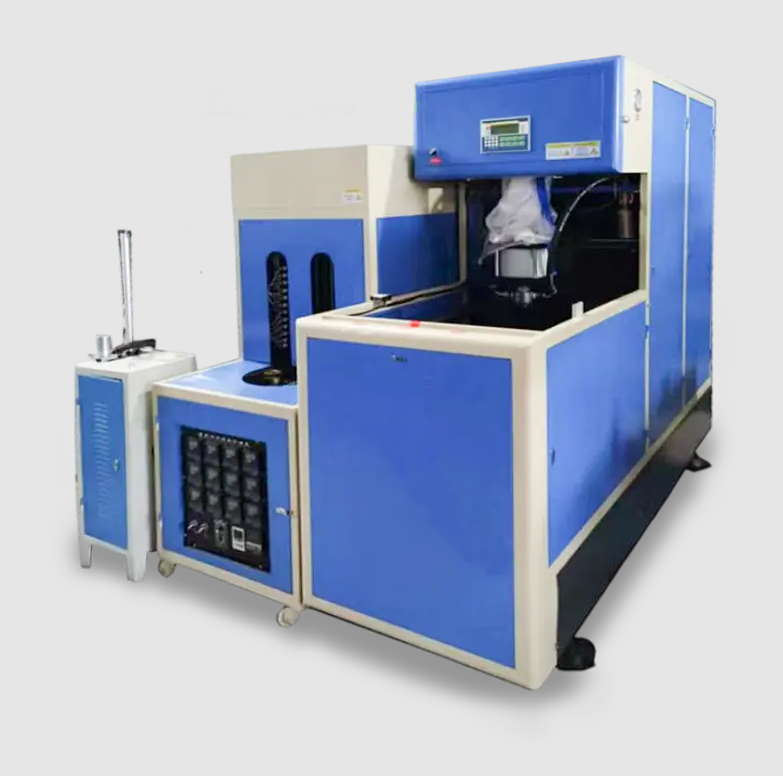

The Wide-Mouth Bottle Blowing Machine and Edible Oil Bottle Blowing Machine are commonly used equipment in modern packaging production lines. These machines allow manufacturers to produce containers with consistent shapes and dimensions, suitable for a range of liquid products. The design of wide-mouth machines accommodates larger bottle openings, which can simplify filling processes, while edible oil bottle machines are specifically configured to handle oils without compromising container integrity. Understanding the specific requirements of both types of machinery is essential to achieving steady output and maintaining quality standards.

Wide-mouth bottle blowing equipment typically operates using an extrusion blow molding method, where a tube of plastic, known as a parison, is extruded vertically into a mold. Air pressure then inflates the parison to take the shape of the mold cavity. For edible oil containers, the machine may include additional features to ensure smooth wall distribution and prevent leaks. Temperature control systems are often integrated to maintain material consistency, especially when dealing with plastics prone to uneven cooling. Operators monitor these parameters closely to reduce material waste and avoid defects such as thin walls or surface inconsistencies.

When selecting a Wide-Mouth Bottle Blowing Machine, production capacity is a primary factor. Machines vary in output rates, ranging from a few hundred to several thousand bottles per hour. Manufacturers must match machine speed with the overall production line to avoid bottlenecks. Other considerations include mold versatility, ease of cleaning, and automation level. Advanced control systems allow operators to adjust parameters such as blow pressure, mold temperature, and cycle duration, which can improve product consistency without requiring manual intervention. In parallel, choosing an Edible Oil Bottle Blowing Machine requires attention to chemical compatibility with the oil type. Certain oils may interact with specific polymers, so selecting a machine that accommodates a suitable range of plastics ensures that containers maintain integrity over time.

Maintenance is a key aspect of both wide-mouth and edible oil bottle production equipment. Regular inspection of molds, blow pins, and heating elements helps prevent unexpected downtime. Lubrication schedules for moving components, along with routine cleaning, reduce wear and tear. Some manufacturers implement preventive maintenance programs that include monitoring cycle counts and temperature logs to anticipate potential failures. Staff training is also essential, as proper handling and adjustment of equipment contribute to consistent output and reduce operational errors.

Automation is increasingly common in modern bottle production. Wide-mouth machines can be integrated with robotic handling systems for demolding and conveying bottles to filling stations. Similarly, edible oil bottle machines may include automatic parison cutting and trimming devices to streamline post-processing. These automated systems not only improve efficiency but also reduce manual labor requirements, ensuring a safer working environment. Despite automation, operator oversight remains critical for monitoring process parameters and ensuring the quality of produced bottles.

Energy consumption is another factor considered during machine selection. Both types of machines may utilize significant electrical power for heating, air compression, and motor operation. Manufacturers often compare energy ratings and cycle efficiency to optimize production costs. Some machines offer features like variable frequency drives for motors or staged heating zones to reduce energy usage while maintaining performance. Operational efficiency can also be enhanced by scheduling production runs to maximize machine utilization and minimize idle time.

Material handling plays a role in overall production efficiency. Wide-mouth bottles are often larger and heavier, requiring robust conveying and packaging systems. For edible oil bottles, preventing contamination during handling is critical, as oils can degrade or react with residual cleaning agents. Machine designs often include smooth surfaces and accessible mold areas to simplify cleaning and reduce contamination risks. Standardized procedures for material loading and product removal contribute to smoother production cycles.