Preform mold technology is a central element in producing PET bottles and other plastic containers. A Preform mold shapes polymer material into a preliminary form that will later be expanded into the final container through blow molding. The precision of the mold determines the uniformity of the preforms and the reliability of subsequent production processes.

Injection molding is the standard method for creating preforms in a Preform mold. Molten polymer is injected into the mold cavity under high pressure, filling every contour to achieve the intended shape. Uniform cooling ensures that the preform maintains consistent wall thickness and surface appearance. Inconsistent cooling can result in defects such as sink marks, warping, or uneven weight distribution.

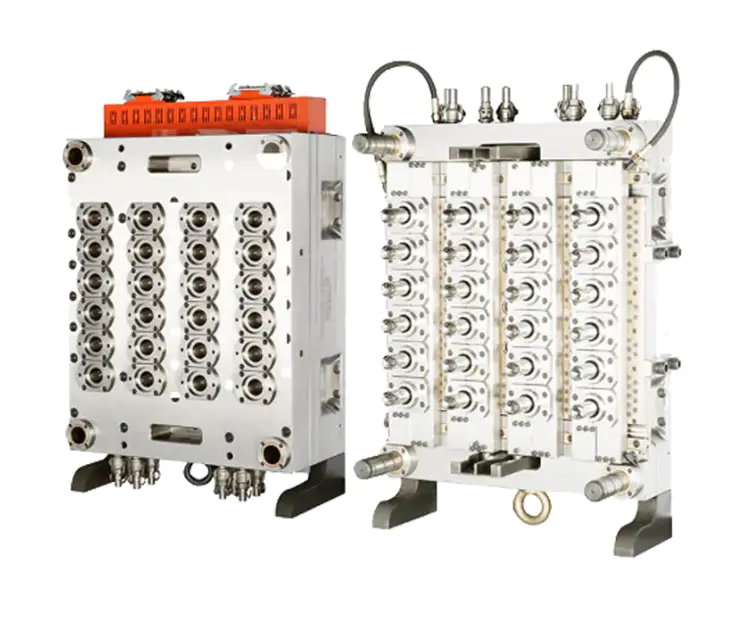

Mold construction requires attention to mechanical strength and wear resistance. Preform molds are typically made from hardened steels or alloy materials that resist high-temperature cycling. Surface treatments, including polishing and plating, reduce friction between the mold and the polymer, enhancing material flow and preventing sticking. These factors contribute to longer mold life and stable production performance.

The shape of the cavity in a Preform mold is designed with careful consideration of the bottle’s final use. The preform’s neck, body, and base geometry affect blow molding efficiency and container strength. Flow simulation and finite element analysis are often used to optimize mold design, improving polymer distribution and reducing cycle time. These tools help identify potential problem areas before mold fabrication.

Preform molds can support different preform sizes, weights, and neck finishes. Modular designs allow adjustments without replacing the entire mold, providing flexibility for various production runs. This adaptability reduces investment costs while maintaining consistent quality. Manufacturers can switch between product lines efficiently using the same mold base.

Cooling systems are integrated into Preform molds to ensure rapid solidification of the polymer. Water channels, oil circuits, or other cooling solutions remove heat effectively, reducing cycle time and maintaining dimensional stability. Proper cooling supports high-speed production and minimizes energy usage. Consistent thermal management is essential for maintaining the precision of the molded preforms.

Regular maintenance is necessary for Preform molds to retain performance. Inspection of cavity surfaces, runners, and ejector systems helps identify wear or damage. Cleaning and polishing prevent build-up and maintain mold efficiency. Timely maintenance reduces downtime and ensures that the preforms produced meet quality standards consistently.

In modern packaging, Preform molds are indispensable. They provide precision shaping, control over wall thickness, and flexibility to accommodate different container designs. Advances in material technology, mold construction, and thermal management continue to enhance the efficiency and reliability of preform production. Preform molds remain a key component in the manufacturing of plastic bottles and containers.