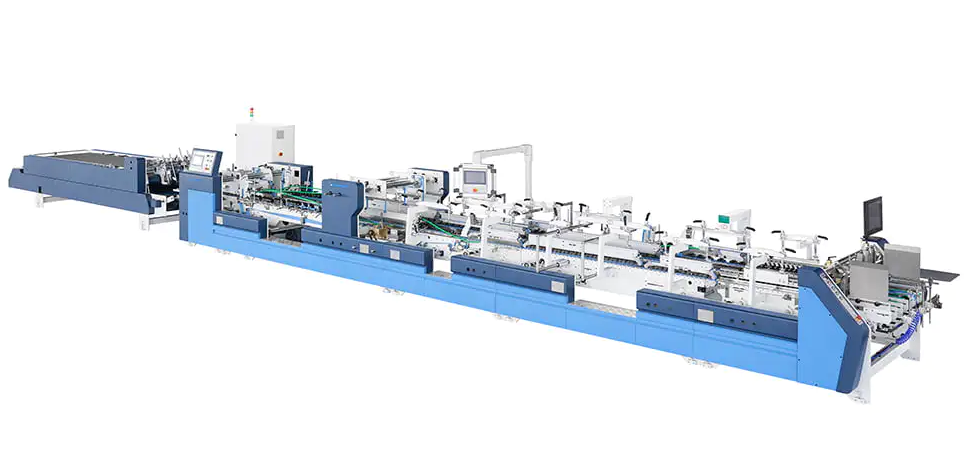

An automatic box folder is a machine designed to fold paperboard blanks into boxes efficiently and accurately. It provides a streamlined solution for packaging production, reducing the need for manual handling while maintaining consistent quality.

The machine typically features a feeding system, folding stations, and adjustable guides. The feeding system ensures a continuous supply of blanks, while folding stations create precise creases to prepare the material for assembly. Adjustable guides and settings allow the machine to handle various box sizes and types.

Automatic box folders can process different carton styles, including tuck-end boxes and regular slotted containers. Operators can adjust speed, folding angles, and pressure to match material thickness and production requirements. Routine maintenance, such as cleaning rollers and checking alignment, is important to maintain efficiency and prevent downtime. Safety features are also included to protect operators.

These machines are widely used in industries such as food packaging, pharmaceuticals, and consumer products. By automating the folding process, manufacturers can improve production speed, reduce labor costs, and maintain consistent quality. The machine also helps minimize errors, ensuring that boxes are accurately folded and ready for further processing or shipment.

In summary, an automatic box folder enhances packaging operations by combining efficiency, accuracy, and reliability. It provides manufacturers with a practical solution for producing high-quality boxes with minimal manual intervention.