In today’s highly automated and competitive industrial landscape, precision measurement is a critical determinant of product quality and process stability. Whether it’s in packaging machinery, automotive components, or electronic assemblies, even the smallest deviation can lead to inefficiency or system malfunction. Among the tools that define dimensional accuracy, the general digital vernier caliper stands out as an indispensable instrument.

At West Lake Packaging Machinery, precision is not a concept—it’s a measurable standard. The company integrates general digital vernier calipers throughout its design, assembly, and quality inspection processes, ensuring that every machine part meets exacting specifications.

1. The Role of the General Digital Vernier Caliper in Modern Production

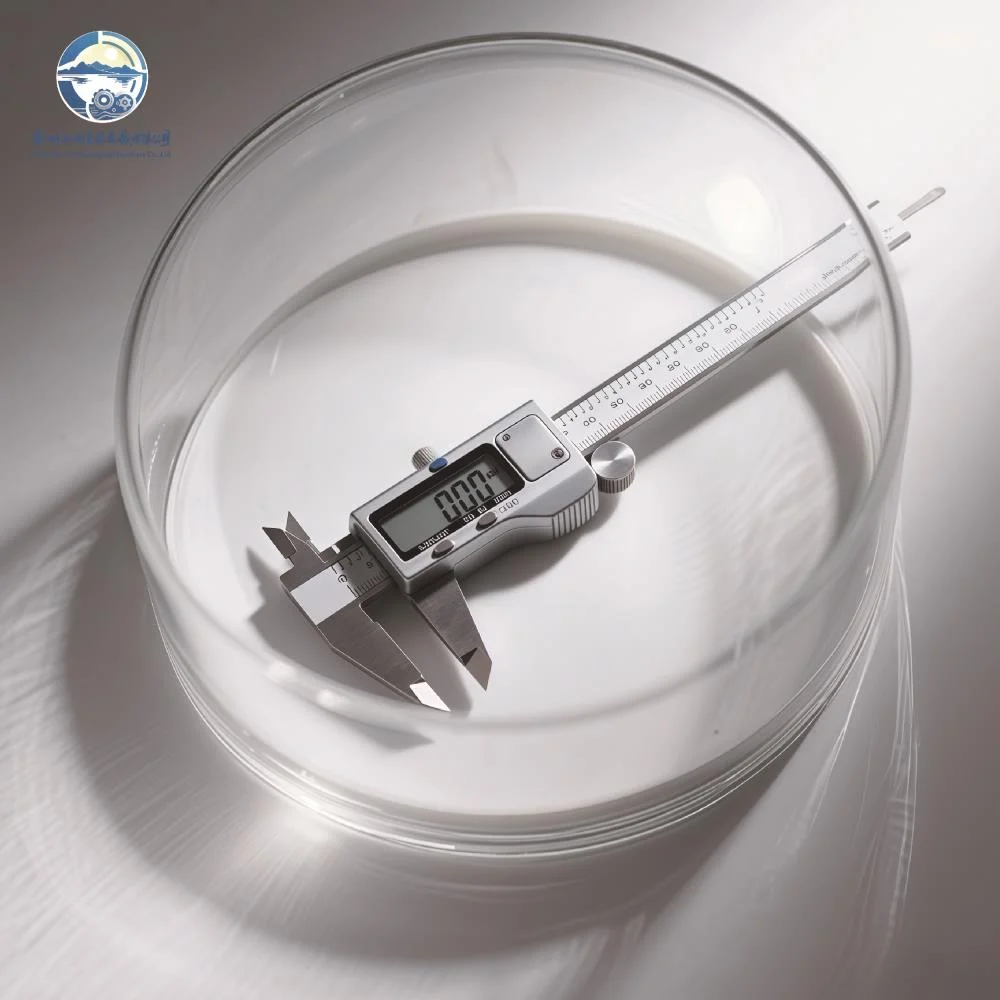

A general digital vernier caliper is more than a measuring device—it’s a bridge between engineering design and manufacturing reality.

Equipped with a high-resolution digital display, it allows users to read measurements instantly, eliminating human reading errors common with analog scales. The tool measures internal dimensions, external dimensions, and depths with exceptional precision, typically up to 0.01 mm accuracy.

In the context of West Lake Packaging Machinery, digital vernier calipers are essential for checking the alignment of mechanical components such as sealing jaws, conveyor shafts, guide rails, and pneumatic assemblies. Maintaining tight tolerances in these parts ensures smooth operation, reduced vibration, and longer equipment lifespan.

2. Engineering Accuracy and Measurement Reliability

The accuracy of a general digital vernier caliper depends on several engineering parameters:

Material stability – Hardened stainless steel reduces thermal expansion and improves long-term durability.

Sensor calibration – Precision linear encoders ensure consistent digital readings over time.

Data output capability – Modern models allow USB or Bluetooth data transfer for digital quality tracking.

West Lake Packaging Machinery employs calibrated digital vernier calipers from globally recognized metrology brands, performing periodic recalibration under ISO 9001-certified procedures. This rigorous quality approach guarantees that every measurement taken directly supports the company’s zero-defect manufacturing goals.

3. Digital Integration and Smart Data Collection

As manufacturing transitions toward Industry 4.0, measurement tools are no longer isolated instruments—they are part of a connected data ecosystem.

Modern general digital vernier calipers can transmit measurement data to centralized quality control software. This integration allows engineers at West Lake Packaging Machinery to record, analyze, and verify dimensional data in real time, identifying any potential deviation before it impacts production.

Such data-driven inspection systems enhance traceability and compliance, aligning with the company’s commitment to continuous improvement and precision packaging technology.

4. Application Scenarios in Packaging Equipment Manufacturing

In the field of packaging machinery, precision is particularly critical due to the interaction of multiple mechanical and pneumatic systems.

West Lake Packaging Machinery utilizes general digital vernier calipers during several key stages:

Component Inspection: Ensuring each machined part conforms to dimensional drawings before assembly.

Assembly Verification: Confirming spacing, clearance, and fit between moving parts.

Maintenance and Calibration: Checking for wear or dimensional drift in long-term service.

Final Quality Testing: Verifying critical dimensions before shipping finished equipment.

Through these applications, the company ensures operational consistency, optimal sealing performance, and reduced mechanical failure rates.

5. Advantages of Using General Digital Vernier Calipers

Compared with traditional mechanical calipers, digital models offer a series of advantages crucial to industrial precision:

-

Instant digital readout for faster operation and reduced human error.

-

Metric and imperial conversion for cross-market engineering projects.

-

Zero setting at any position to measure differential dimensions easily.

-

Automatic power-off and energy-saving design for extended tool life.

-

High repeatability and calibration traceability, ensuring confidence in every measurement.

These benefits directly contribute to West Lake Packaging Machinery’s reputation for high-performance, precision-engineered packaging systems.

6. Precision as a Competitive Edge

In an industry where tolerances define competitiveness, maintaining strict dimensional accuracy is both a challenge and a differentiator.

By integrating general digital vernier calipers into every stage of its workflow—from design to assembly—West Lake Packaging Machinery has achieved measurable gains in efficiency, reliability, and customer satisfaction.

Each reading taken from a caliper reflects more than a measurement—it represents the company’s pursuit of engineering perfection.

Conclusion: Building Trust Through Precision

The general digital vernier caliper may appear to be a simple instrument, but in industrial manufacturing, it forms the foundation of quality assurance.

For West Lake Packaging Machinery, it is not merely a tool but a philosophy—ensuring that every part, every machine, and every package meets the highest standards of precision and performance.

In the pursuit of excellence, precision is not optional—it’s measurable.

For more product details, please visit:

General Digital Vernier Caliper – West Lake Packaging Machinery