In high-performance industries such as aerospace, automotive, medical devices, and chemical processing, material selection is crucial for reliability, weight reduction, and corrosion resistance. Titanium turning parts are widely recognized for their unique combination of high strength, low density, and exceptional corrosion resistance. These characteristics make them indispensable in critical applications where conventional metals fall short.

AICHI TECHNOLOGY has been a leading provider of precision titanium components, delivering high-quality turning parts with stringent tolerances and superior surface finishes. By integrating advanced machining processes, the company ensures that each component meets rigorous industry standards.

Understanding Titanium Turning Parts

What Are Titanium Turning Parts

Titanium turning parts are precision components produced by turning operations on titanium alloys, including grades such as Ti-6Al-4V, commercially pure titanium (CP-Ti), and other specialty alloys. Turning involves rotating the titanium workpiece while a cutting tool shapes it to the desired diameter, length, and contour.

Key Advantages

-

Lightweight Strength: Titanium’s strength-to-weight ratio exceeds many steels, reducing overall component weight without compromising durability.

-

Corrosion Resistance: Resistant to saltwater, acids, and industrial chemicals, making them ideal for harsh environments.

-

Biocompatibility: Suitable for medical implants and surgical instruments.

-

Temperature Tolerance: Retains mechanical properties at elevated temperatures, essential for aerospace and automotive applications.

Material Selection Considerations

Selecting the right titanium alloy is critical for turning operations:

-

CP Titanium (Grades 1–4): Highly corrosion-resistant, excellent ductility, suitable for chemical and marine environments.

-

Ti-6Al-4V (Grade 5): The most widely used alloy in aerospace and medical applications; offers high strength and fatigue resistance.

-

Specialty Alloys: Tailored for extreme conditions, such as high-temperature resistance or enhanced wear performance.

AICHI TECHNOLOGY applies strict material testing to ensure mechanical properties and purity meet client specifications, enabling reliable performance across demanding applications.

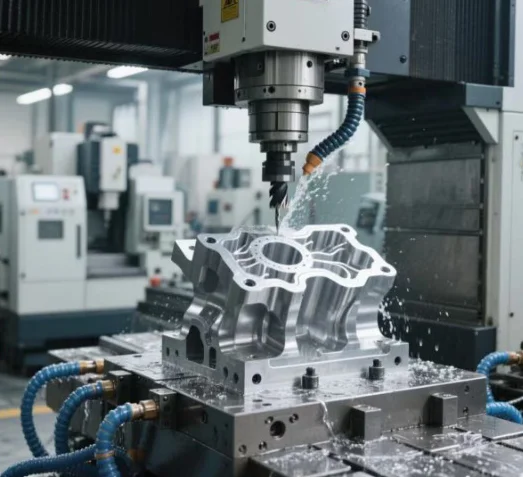

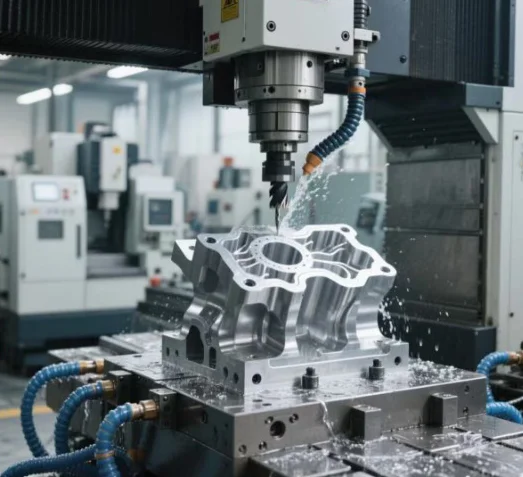

Advanced Turning Processes

Turning titanium is challenging due to its low thermal conductivity, high strength, and chemical reactivity with cutting tools. Advanced turning processes include:

-

CNC Precision Turning: Computer-controlled operations provide tight tolerances, typically ±0.01 mm, ensuring repeatable quality.

-

Tooling Considerations: Use of carbide or coated inserts to minimize tool wear and maintain surface integrity.

-

Cutting Parameters: Optimized feed rates, spindle speeds, and cooling strategies to prevent workpiece deformation and tool oxidation.

-

Coolant and Lubrication: High-pressure coolants and specialized lubricants reduce heat and improve surface finish.

By employing these techniques, AICHI TECHNOLOGY achieves high-efficiency production with minimal scrap and consistent quality.

Surface Finishing and Post-Processing

After turning, titanium parts often require post-processing to meet functional and aesthetic requirements:

-

Polishing and Buffing: Smoothens surface for reduced friction and improved fatigue life.

-

Anodizing: Enhances corrosion resistance and provides color coding for assembly or identification.

-

Threading and Grooving: Precision features for mechanical assembly in aerospace, automotive, or medical devices.

-

Heat Treatment: Stress-relieves components to improve dimensional stability and mechanical performance.

These finishing steps are essential for high-performance titanium turning parts, and AICHI TECHNOLOGY ensures compliance with tight industry tolerances.

Applications Across Industries

Aerospace

Titanium turning parts are used in engine components, fasteners, brackets, and structural parts, where lightweight and high strength are critical. The ability to withstand high temperatures and corrosive environments makes titanium ideal for aviation.

Medical Devices

Precision components for surgical instruments, implants, and prosthetics rely on biocompatible titanium alloys, ensuring safety and longevity.

Automotive

High-performance vehicles use titanium turning parts for engine valves, suspension components, and exhaust systems, optimizing weight reduction and improving fuel efficiency.

Chemical and Marine Industries

Corrosion-resistant titanium fittings, connectors, and valves withstand aggressive chemicals and saltwater, extending service life and reducing maintenance costs.

Conclusion

Titanium turning parts combine precision, strength, and corrosion resistance, making them a critical solution in modern industrial applications. AICHI TECHNOLOGY continues to lead in delivering high-quality, reliable components by leveraging advanced CNC turning processes, material expertise, and rigorous quality control. As industries demand higher performance and lighter, more durable components, titanium turning parts will remain at the forefront of innovation.