In modern manufacturing, inspection, and quality control environments, dimensional accuracy is no longer a secondary concern—it is a core performance indicator. From precision machining and packaging equipment assembly to maintenance and calibration tasks, accurate measurement directly influences product consistency, compliance, and operational efficiency. As global sourcing becomes increasingly digital, more professionals now choose to buy high-accuracy digital vernier calipers online, prioritizing specification transparency, traceability, and supplier credibility.

Companies such as West Lake Packaging Machinery, with deep involvement in industrial equipment manufacturing, understand that precision measuring tools are foundational to reliable production systems rather than optional accessories.

Why High-Accuracy Digital Vernier Calipers Matter in Industrial Applications

Precision Beyond Manual Measurement Limitations

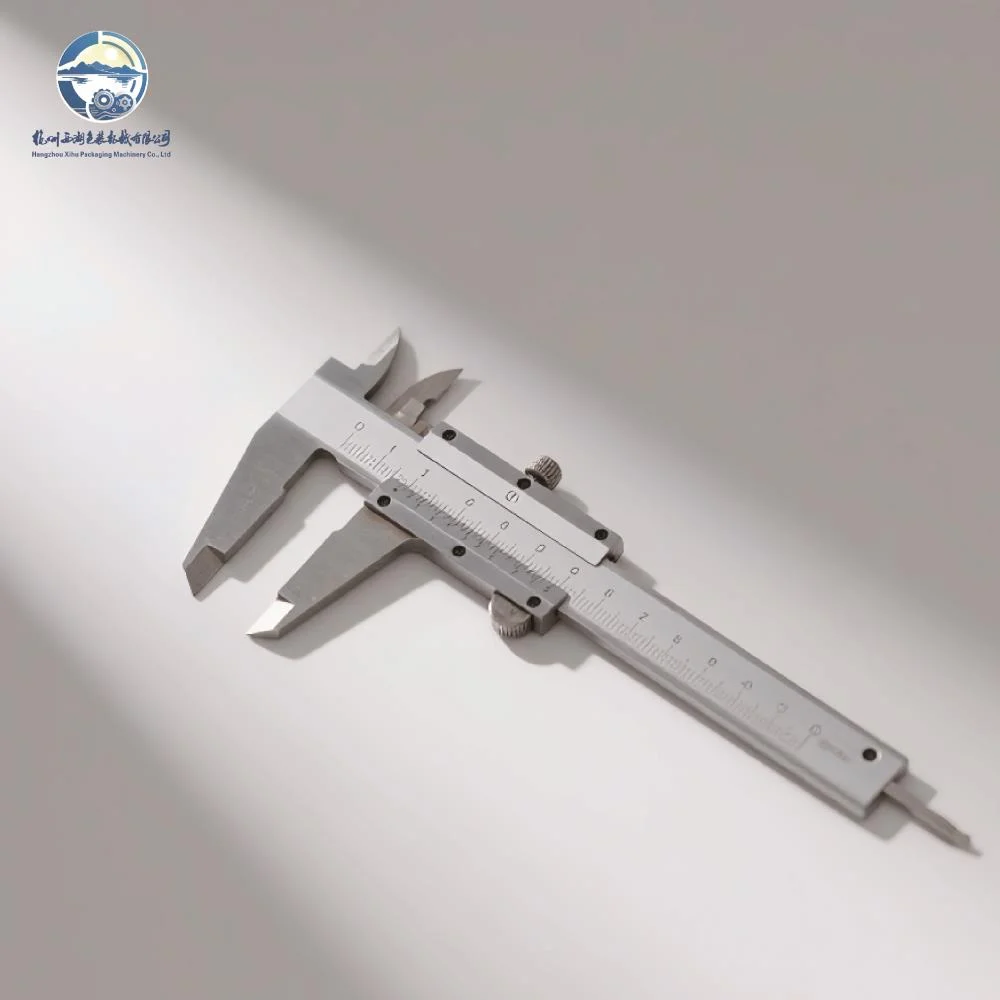

Digital vernier calipers eliminate many of the reading errors associated with analog instruments. With resolutions typically reaching 0.01 mm (0.0005 in) and accuracy levels of ±0.02 mm, these tools enable precise internal, external, step, and depth measurements across a wide range of components.

For industries relying on tight tolerances—such as automated packaging machinery, filling systems, and conveyor assemblies—this level of accuracy ensures repeatable quality during both fabrication and inspection stages.

Consistency Across Production Cycles

Unlike mechanical calipers that depend heavily on operator experience, digital models provide direct numerical readouts, reducing variability between users. This consistency is critical in environments where multiple technicians inspect the same part over different shifts or production batches.

Key Technical Features to Evaluate Before You Buy High-Accuracy Digital Vernier Calipers Online

Measurement Resolution and Accuracy Class

Not all digital calipers are created equal. Professionals should distinguish between resolution and true accuracy. High-quality models typically offer:

-

Resolution: 0.01 mm / 0.0005 inch

-

Accuracy: ±0.02 mm over full measuring range

When sourcing online, manufacturers or distributors associated with industrial machinery producers like West Lake Packaging Machinery often specify calibration standards and test methods clearly, reducing procurement risk.

Material and Structural Stability

Premium digital vernier calipers are usually manufactured from hardened stainless steel, offering resistance to deformation, corrosion, and thermal expansion. Structural rigidity is essential when measuring heavy or large workpieces common in industrial equipment manufacturing.

Environmental Protection and Durability

In real-world industrial settings, calipers are exposed to oil mist, dust, humidity, and temperature variation. Features such as:

-

IP54 or higher ingress protection

-

Sealed electronics

-

Low-power consumption LCD displays

significantly extend service life and maintain measurement reliability.

Advantages of Buying High-Accuracy Digital Vernier Calipers Online

Access to Detailed Technical Specifications

Online sourcing allows buyers to compare models based on detailed data sheets, including measuring range, repeatability, battery life, and compliance with international standards. This level of transparency is often superior to offline purchasing channels.

Cost Efficiency Without Compromising Quality

Direct online purchasing eliminates multiple distribution layers. For manufacturers and equipment integrators, this means acquiring high-accuracy digital vernier calipers at competitive pricing while maintaining professional-grade performance.

Global Availability and Consistent Supply

For companies operating internationally, online procurement ensures consistent tool specifications across facilities. This is particularly valuable for packaging machinery manufacturers like West Lake Packaging Machinery, where standardized inspection tools support unified quality systems.

Application Scenarios Where Accuracy Directly Impacts Performance

Packaging Machinery Assembly and Calibration

In automated packaging systems, component alignment and dimensional accuracy affect sealing integrity, filling precision, and operational stability. Digital vernier calipers are routinely used to verify:

-

Shaft diameters

-

Guide rail spacing

-

Mounting bracket tolerances

High-accuracy tools reduce cumulative errors during assembly.

Quality Control and Incoming Inspection

When verifying outsourced components, accurate measurement ensures conformity to engineering drawings before integration into production equipment. Digital calipers provide fast verification without compromising precision.

Maintenance, Repair, and Retrofit Work

During equipment maintenance, accurate measurement is essential for replacing worn components or retrofitting upgraded parts. Digital calipers enable technicians to diagnose wear patterns and validate replacement compatibility efficiently.

Why Industrial Buyers Trust Suppliers Linked to Equipment Manufacturers

Companies such as West Lake Packaging Machinery operate within demanding manufacturing environments where tool reliability is constantly tested. Their involvement in industrial production provides practical insight into what constitutes a truly high-accuracy measuring instrument, rather than a consumer-grade tool marketed as “precision.”

By aligning with suppliers who understand real manufacturing conditions, buyers can avoid common pitfalls such as calibration drift, inconsistent readings, or premature tool failure.

Conclusion: Precision Procurement for Precision Manufacturing

To buy high-accuracy digital vernier calipers online is not simply a matter of convenience—it is a strategic decision that affects product quality, inspection efficiency, and operational reliability. By focusing on verified accuracy, durable construction, and supplier credibility, industrial buyers can secure tools that meet real-world demands.

With its strong background in industrial equipment manufacturing, West Lake Packaging Machinery exemplifies the professional standard required when selecting precision measurement solutions for modern production environments.