Industrial filtration is evolving rapidly as process environments become more demanding, temperatures rise, and operating conditions require more robust, long-lasting solutions. In sectors such as petrochemicals, power generation, fine chemicals, hydraulic systems, and gas processing, conventional polymer-based filters can no longer satisfy the requirements for thermal resistance, mechanical strength, and filter precision.

This is why the metal pleated filter cartridge has become the preferred choice for high-stress, high-contaminant, and high-efficiency applications. With extensive engineering expertise, HEALU has positioned itself as a reliable manufacturer delivering metal filter cartridges capable of meeting multidimensional industrial needs: durability, consistent filtration accuracy, and exceptional structural stability.

Understanding the Metal Pleated Filter Cartridge

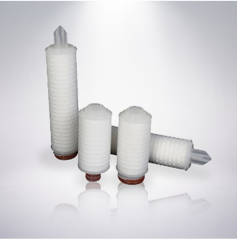

Unlike traditional disposable filters, metal pleated filter cartridges are constructed from stainless steel wire mesh, sintered fiber felt, or multilayer metallic laminates. The pleating process increases surface area exponentially, enhancing both dirt-holding capacity and filtration efficiency.

Key advantages include:

-

High-temperature resistance (up to 500°C depending on alloy)

-

Corrosion resistance for chemical media and harsh environments

-

Washability and reusability, significantly lowering operating costs

-

Precise filtration accuracy ranging from 1–100 microns

-

Robust mechanical properties under fluctuating pressures

HEALU custom-engineers these cartridges to ensure stability under prolonged operational cycles.

Core Engineering Features That Define Performance

1. Pleated Structure for Maximum Loading Capacity

The pleated geometry increases effective filtration area by several times, enabling:

Longer service cycle

Lower differential pressure

Higher flow rates under the same footprint

HEALU optimizes pleat geometry through controlled spacing, uniform depth, and thermal shaping to ensure that the pleats do not collapse or deform.

2. Multilayer Metal Media for Precision and Stability

A high-quality metal pleated filter cartridge depends on the filtration media. HEALU primarily uses:

Sintered stainless steel fiber felt for ultra-fine filtration

Sintered wire mesh for structural support and high mechanical strength

316L stainless steel for chemical and corrosion resistance

The multilayer metal matrix ensures that filtration precision does not decrease even after repeated cleaning cycles.

3. Superior Thermal and Chemical Resistance

Unlike polymer filters that deform at 120–150°C, metal pleated cartridges maintain structure and performance under:

High-temperature gas filtration

Steam purification

Solvent and acid exposure

High-pressure hydraulic conditions

HEALU conducts thermal cycling tests to ensure long-term stability in these conditions.

4. Reusability and Reduced Lifecycle Cost

A major economic advantage of metal pleated filter cartridges is their reusability. They can undergo:

Ultrasonic cleaning

Chemical rinsing

Reverse flushing

Thermal regeneration

This sustainability feature helps industries reduce filter consumption and maintenance downtime. HEALU’s cartridges are engineered to retain pore integrity after multiple cleaning cycles.

Industrial Applications Where Metal Pleated Filters Are Indispensable

1. Petrochemical Refining

Used for filtration of:

Catalysts

Polymer melts

Chemical solvents

Hydrogen purification

Stainless steel pleated cartridges ensure controlled particulate removal without leaching or degradation.

2. Power Generation

In gas turbine and steam turbine systems, metal pleated cartridges are essential for:

Fuel gas filtration

Lubrication systems

Hydraulic circuits

HEALU designs high-pressure-resistant cartridges for long-term turbine protection.

3. Food & Pharmaceutical Processing

Although metal filters cannot be used universally, stainless steel cartridges excel in:

High-temperature steam filtration

Gas purification

High-purity liquid processing

Their cleanability and inert material properties align with industry hygiene standards.

4. Natural Gas and Hydrogen Systems

Metal pleated filter cartridges withstand high-pressure gas filtration, ensuring:

Removal of mechanical impurities

Stable flow

Prevention of compressor damage

HEALU’s reinforced end caps and welded seams ensure leak-free structural integrity.

5. Hydraulic and Lubrication Systems

Metal cartridges outperform synthetic filters due to:

Higher dirt capacity

Resistance to pressure spikes

Stable micron retention under pulsating flow

This makes stainless steel pleated cartridges essential for high-performance hydraulic machinery.

Why HEALU Is a Trusted Manufacturer in Metal Pleated Filtration

HEALU’s engineering approach distinguishes its products in several ways:

Precision Manufacturing Process

Every cartridge undergoes:

Laser cutting

Precision pleating

TIG welding

Integrated quality inspection

This ensures dimensional accuracy, uniform media distribution, and leak-free construction.

Customizable Filtration Performance

HEALU provides custom options including:

Filtration rating (1–100 microns)

Cartridge length and diameter

End cap types (DOE, SOE, threaded, flange)

Metal alloy selection (304/316L/904L/Monel)

Such flexibility supports equipment-specific integration.

Strict Quality Control

HEALU’s process includes:

Bubble point testing

Flow rate validation

Thermal stability assessments

Corrosion resistance evaluation

This ensures each metal pleated filter cartridge meets stringent operational standards.

Conclusion: A Long-Term Solution for Modern Industry

In today’s industrial environments, where filtration demands exceed the capabilities of disposable polymer cartridges, the metal pleated filter cartridge stands out as a high-performance, long-lifespan, and cost-effective solution. With its advanced engineering and strict quality standards, HEALU provides filtration equipment that ensures operational reliability across multiple industries.

For systems requiring precision, durability, and consistent filtration performance, metal pleated filter cartridges remain the smartest investment — and HEALU continues to set the benchmark for quality.

https://www.healuair.com/engineering-durability-the-science-behind-metal-pleated-filtration.html