When designing a coal handling system, engineers must carefully plan the integration of a Coal Plants Vibrator. The goal is to ensure that the vibration system effectively mobilizes the stored coal but does not compromise structural integrity or safety. One crucial factor is mounting: the vibrator must be attached in a way that transmits force efficiently without overstressing the hopper or silo walls.

A well-designed Coal Conveying Vibrator system considers the direction and amplitude of vibration. The vibration angle determines how material moves; too shallow an angle may not sufficiently unstick compacted coal, while too steep can cause overshooting or uneven distribution. Designers often use techniques such as stiffening plates or U-profiles to properly secure external vibrators, ensuring that stress is distributed and the vibration energy is applied where it's most effective.

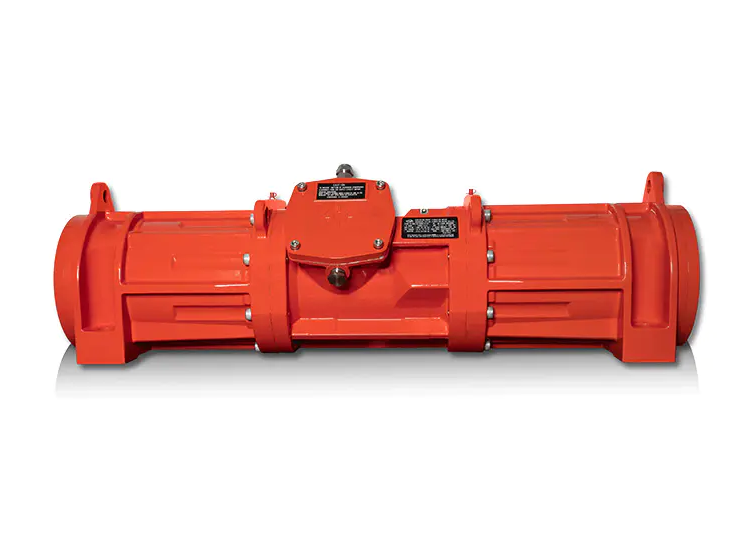

Another design consideration is the type of drive. Electromagnetic vibrators, for example, offer precise control over amplitude and frequency, making them suitable when fine-tuning material flow is required. In contrast, eccentric-block motors may be preferred when a simpler, robust solution is needed.

Thermal and mechanical durability is also essential. Coal-handling facilities often face harsh conditions: dust, varying temperatures, and heavy loads. The vibrator must be built to withstand these without frequent failures. For instance, engineers must ensure that the spring support and elastic systems around the vibrator are well matched to absorb vibration without transmitting harmful stress to the main structure.

In conveyor applications, placing a Coal Conveying Vibrator at strategic transfer points can significantly reduce buildup and bridging. For example, near feeders or chutes, vibration can prevent coal from settling or arching. This leads to a smoother, more reliable feed into downstream systems like belt conveyors.

Safety and serviceability also need to be addressed. Engineers should design access points for vibrator inspection, allow for replacement, and include sensors or maintenance schedules to monitor current consumption and amplitude. These proactive steps help reduce unplanned downtime and ensure long-term performance.

Choosing a reputable manufacturer, such as Shenzhen Putian Vibration Motor Co., Ltd., can simplify this process. Their expertise in vibration motor design tailored for coal-handling environments can guide engineering teams in selecting the right vibratory force, mounting strategy, and drive system. By aligning the design of both a Coal Plants Vibrator and a Coal Conveying Vibrator, engineers can build a robust, efficient, and safe coal handling facility.