In the textile industry, ensuring the durability of fabrics is crucial for maintaining consumer satisfaction and product quality. One key aspect of durability is washing fastness, which refers to the ability of textile colors to withstand the effects of washing and dry cleaning. To assess this property, textile manufacturers rely on washing fastness testers.

Working Principles of Washing Fastness Testers

Washing fastness testers simulate the washing and dry cleaning processes to evaluate the color stability of textiles. The fundamental working principles involve exposing fabric samples to controlled washing conditions, including detergent solutions, temperatures, and agitation levels, and then assessing any color change or dye transfer.

-

Sample Preparation: Fabric swatches are cut to standard sizes and prepared according to test protocols.

-

Washing Conditions: The tester subjects the samples to specific washing conditions, such as water temperature, detergent type and concentration, and wash cycle duration.

-

Agitation: Mechanical agitation simulates the action of a washing machine, ensuring even distribution of detergent and water.

-

Drying: After washing, samples are dried either naturally or using a drying cabinet to standardize the evaluation conditions.

-

Evaluation: Color change and dye transfer are assessed using standardized gray scales or instrumental color measurement.

Selection Guide for Washing Fastness Testers

When choosing a washing fastness tester, several factors need to be considered to ensure it meets the specific needs of your textile testing laboratory.

-

Test Capacity: Determine the number of samples you need to test simultaneously. Larger testers can accommodate more samples, increasing efficiency.

-

Temperature Control: Precision temperature control is crucial for accurate simulation of washing conditions. Look for testers with digital thermostats and temperature stability features.

-

Agitation Mechanisms: Different agitation methods (e.g., pulsator, drum rotation) simulate various washing machine types. Choose the one that best aligns with your test requirements.

-

Automation Level: Fully automated testers can streamline testing processes, reduce human error, and provide consistent results. Semi-automatic or manual testers may be more suitable for budget-conscious labs.

-

Compatibility with Standards: Ensure the tester complies with relevant international standards to ensure test results are recognized globally.

-

After-Sales Support: Reliable after-sales service, including training, maintenance, and parts availability, is essential for the long-term performance of your tester.

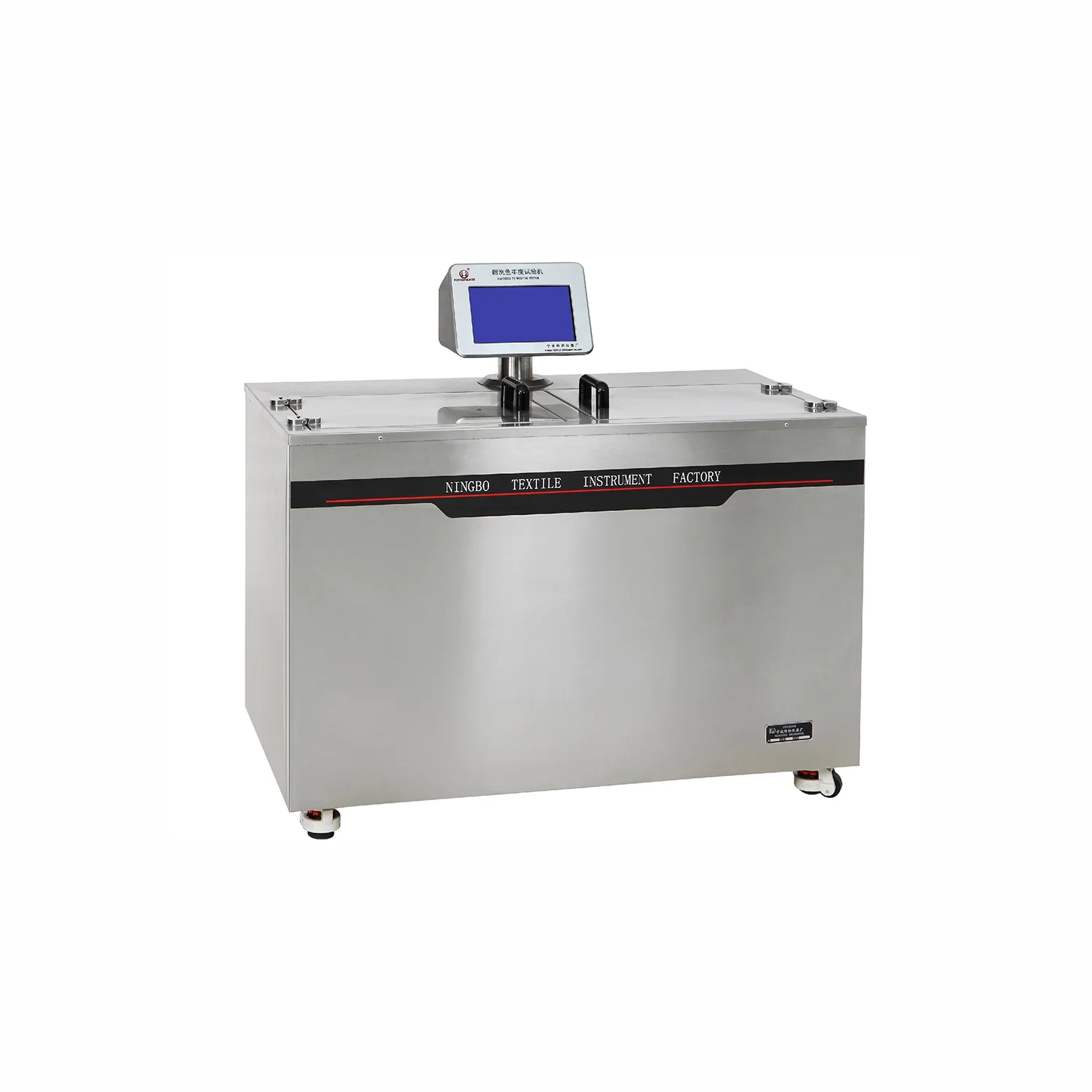

Ningbo Textile Instrument Factory: Selling Points

Ningbo Textile Instrument Factory stands out in the market for its high-quality washing fastness testers, renowned for their precision, reliability, and versatility. Here are some key selling points:

-

Comprehensive Range: Ningbo offers a wide range of washing fastness testers, catering to different testing needs, from basic models to advanced, fully automated systems.

-

Advanced Technology: Incorporating the latest technology, Ningbo's testers ensure accurate temperature control, precise agitation, and consistent test results.

-

Compliance with Standards: All testers are designed to comply with international standards, ensuring test results are recognized worldwide.

-

User-Friendly Interface: The intuitive control panels and software make it easy for operators to set test parameters, monitor progress, and analyze results.

-

Customization Options: Ningbo offers customization options to tailor testers to specific customer requirements, ensuring maximum efficiency and relevance.

-

Robust Construction: Built with high-quality materials, Ningbo's testers are durable and designed to withstand the rigors of daily use in busy testing laboratories.

-

Excellent After-Sales Support: Committed to customer satisfaction, Ningbo provides comprehensive after-sales support, including installation, training, and ongoing maintenance services.

Highlight: Testing Capabilities for Various Textiles

Used for testing the color fastness to washing and dry cleaning of cotton, wool, silk, hemp, chemical fiber, and other textiles, Ningbo Textile Instrument Factory's washing fastness testers demonstrate versatility and precision. Whether you are testing delicate silk scarves or robust cotton denim, Ningbo's testers provide reliable results, helping you ensure the durability of your textiles.

-

Cotton: Tests can simulate domestic and industrial washing conditions to evaluate color stability.

-

Wool: Special wool-safe detergents and gentle agitation settings ensure accurate testing without damaging the fibers.

-

Silk: Delicate silk fabrics can be tested using mild conditions to assess their color retention.

-

Hemp: Robust testing simulates heavy-duty washing cycles to evaluate color fastness in durable fabrics.

-

Chemical Fibers: Tests can accommodate various synthetic fibers, assessing color stability under different washing conditions.

Conclusion

Ensuring the washing fastness of textiles is vital for maintaining product quality and consumer satisfaction. Ningbo Textile Instrument Factory's washing fastness testers, with their advanced technology, compliance with standards, user-friendly interfaces, and excellent after-sales support, are ideal for textile manufacturers seeking reliable and versatile testing solutions. By understanding the working principles and selecting the right tester, textile labs can confidently assess the durability of their fabrics, contributing to the overall success of their products in the market.