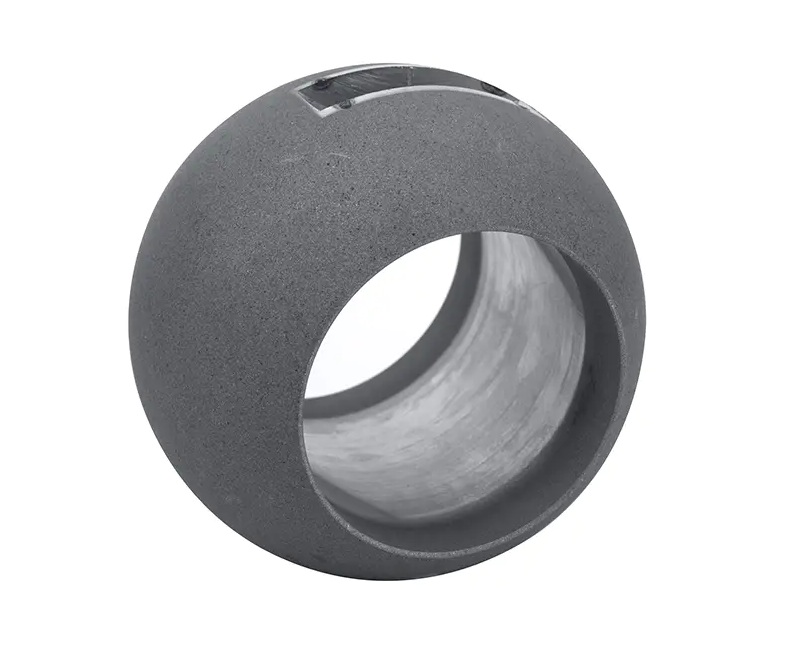

For years, many plant operators have worked around imperfect systems. They’ve learned to “feel” when the valve needs extra torque or to anticipate minor leaks as part of the job. But what if the difference between ordinary and effortless operation came from a single overlooked component? That’s where innovation from a Ball Valve Ball factory quietly changes the story

.

.

The old experience: every shutdown or restart meant manual checks, uncertain sealing, and unnecessary energy use. The new experience: a valve ball designed with smoother surface precision, reducing wear and sticking without requiring you to change how you work. You still operate as usual—open, close, adjust—but everything feels lighter, more controlled, more certain.

It’s not about adding complex technology; it’s about perfecting the simple movement you already rely on. The best upgrades are the ones you barely notice—because they just work.

This is how practical design meets human routine. A better valve ball doesn’t ask for retraining or new tools. It just fits—cleanly, consistently, silently ensuring your systems stay efficient. The comfort isn’t in seeing it work—it’s in not having to think about it at all.