Medical device manufacturing is evolving quickly, and automation plays a key role in improving production efficiency. A Fully Automated Production Line for Needle-Free IV Connectors is one solution that addresses many challenges faced by manufacturers. It brings precision, speed, and consistency to the production process, making it an attractive option for companies in the medical device industry.

Precision and Accuracy

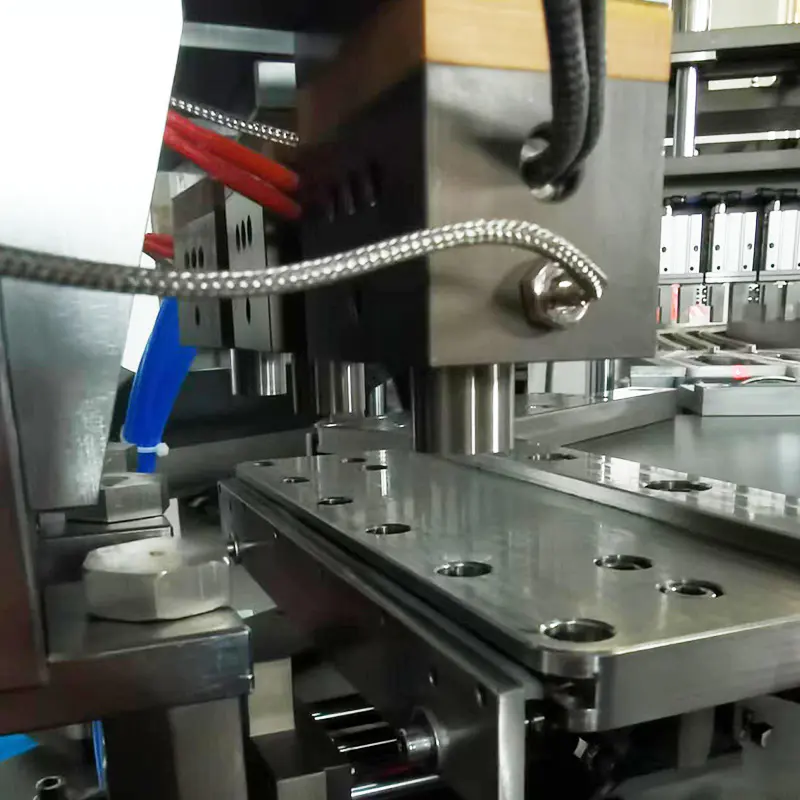

At the core of a Fully Automated Production Line for Needle-Free IV Connectors is advanced control and robotic systems. These systems can handle tiny components with micron-level accuracy, reducing human error and ensuring uniform quality. For manufacturers, this means fewer defects and a more reliable product. Companies looking for a dependable solution often consider the capabilities of the Fully Automated Production Line for Needle-Free IV Connectors Manufacturers, who integrate these features into their equipment.

Efficiency and Productivity

Automation allows for continuous production with minimal downtime. The robotic arms, automated conveyors, and integrated monitoring systems of a Fully Automated Production Line for Needle-Free IV Connectors streamline repetitive tasks. Manufacturers can achieve higher throughput while reducing labor costs. This is especially beneficial for medical device factories that have tight production schedules or high-volume demands. Choosing an experienced Fully Automated Production Line for Needle-Free IV Connectors Manufacturers ensures that efficiency is built into the workflow from the start.

Versatility in Production

Modern production lines are designed to handle different materials, from plastics to delicate biomaterials. A versatile, Fully Automated Production Line for Needle-Free IV Connectors can perform multiple processes,s such as assembly, inspection, and packaging in one integrated system. This flexibility allows manufacturers to adjust production according to changing needs without significant downtime or additional investment. For medical device companies, working with the right Fully Automated Production Line for Needle-Free IV Connectors Manufacturers means access to modular systems that can evolve with their products.

Quality Control and Reliability

High-quality standards are critical in medical device production. A Fully Automated Production Line for Needle-Free IV Connectors often includes vision inspection systems and automated correction mechanisms. This ensures defects are detected early, maintaining compliance and patient safety. Manufacturers benefit from real-time data tracking, which allows them to identify issues before they affect output. Choosing a reputable Fully Automated Production Line for Needle-Free IV Connectors Manufacturers guarantees reliable support and equipment optimized for consistent production.

Investing in a Fully Automated Production Line for Needle-Free IV Connectors is not just about technology; it's about making manufacturing smarter, safer, and more predictable. With enhanced precision, productivity, versatility, and quality control, these production lines provide a strong foundation for medical device manufacturers aiming to compete efficiently in the market.