Check for poor contact of the cable socket connected to formaldehyde detect module wholesale; Or check if the formaldehyde detect module wholesale cable itself is broken, causing the weighing signal to fail to enter the amplifier.

Check whether there is any false welding or open welding at each welding point of the weighing sensor bridge, which may cause the weighing sensor bridge to fail to work. Check the formaldehyde detect module wholesale itself to see if there is any foreign matter or dirt adhering to it, which hinders the elastic deformation of the sensor, so that when a load is applied to the sensor, the elastic body cannot produce elastic deformation normally and the resistance of the resistance strain gauge does not change. This leads to no weighing signal output from the weighing sensor bridge.

When there is no weighing load acting on the electronic pricing scale, the displayed weighing value is not zero, and the displayed value is unstable, constantly changing.

This fault is commonly known as showing zero drift, not returning to zero and jumping characters. The causes of this fault are:

There is a phenomenon of loose connection or open welding on one of the bridge arms of the weighing sensor bridge, or there is a "grounding" phenomenon at a certain welding point. Check if the power supply voltage is stable. If the stability of the power supply voltage is poor, it is also prone to character jumps. The weighing indication is inaccurate.

The reason for this phenomenon is that the elastic body has been dropped or bumped, causing stress to be generated within the elastic body. Or the elastic body breaks locally, causing the strain produced by the elastic body when the weighing load acts on it to be not linear, resulting in inaccurate numbers. The bridge supply voltage is too high, causing the resistance strain gauge to overheat, damaging the adhesive of the strain gauge or changing the resistance value of the strain gauge, resulting in inaccurate readings. The influence of environmental factors.

The electronic pricing scale was once used in high-temperature or humid environments, resulting in a decrease in the insulation resistance value between the strain bridge circuit and the elastic body. Excessive fatigue of the elastomer causes the elastomer to lose its due range of stress variation. When a constant weighing load is added to the electronic pricing scale, the weighing display value changes over time, and the greater the load, the greater the change.

This phenomenon is conventionally referred to as creep, and the main cause of creep is the factor of the adhesive layer. Improper selection of adhesive or aging and deterioration of the adhesive; The strain gauge was adhered in a humid environment, with an overly thick adhesive layer and poor curing of the adhesive layer.

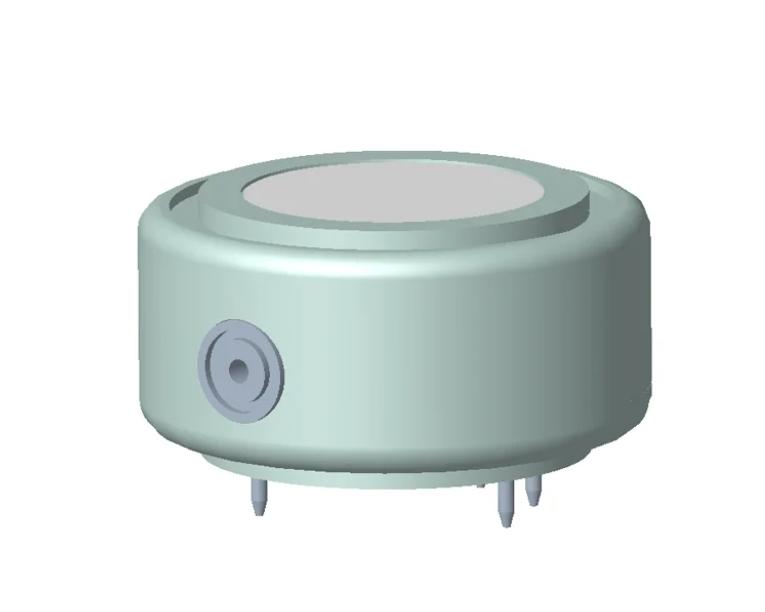

formaldehyde detect module wholesale https://www.cnprosense.com/WH-N-Formaldehyde-gas-sensor.html